About Us

Owned and operated by Olly Warner, Fretronics Engineering specialises in hardware repair, development and consultancy.

Olly originally gained an interest in electronics at an early age from his long standing passion for the RAF’s fast jet squadrons (particularly Tornado GR4s). Fascinated by the engineering behind the fast jets and also having played the guitar from a young age, he developed an interest in the equipment used in live sound production and the engineering behind it. He began modifying guitars and effects pedals in his early teenage years and this developed quickly into designing his own electronics using analog electronics, jellybean logic and basic microcontrollers & software. This carried all the way through high school and into university.

Olly studied at the University of Glasgow and graduated with a Master of Engineering in Electronics and Electrical Engineering with Music – a combined degree studying both music and electronics – and is a member of the Institution of Engineering and Technology. Core elements of the MEng included data acquisition for musical processing, digital signal processing, audio specific programming and analogue/digital electronics. As part of his studies, Olly carried out a six-month placement at Leonardo MW in Edinburgh working on the latest radar technology. During this time, Fretronics Audio was born, taking on basic guitar and effects pedal repairs. By the time Olly came to graduate from university, Fretronics had already built up such a good reputation that it was a natural progression to turn it into a full time business.

Since being fully operational in 2018, Fretronics has grown to be one of the UK’s best repair centres for audio electronics. Now expanding into research and development, Fretronics is taking on contracts for design, consultancy and small scale manufacturing for the electronics industry.

The Workshop

The Bench

The bench – the heart of the workshop. We have three kitted out benches that are fully ESD safe workstations, these holds all of the major test equipment we use and – they’re huge! Plenty of space for anything up to and including large mixing desks can be worked on with ease.

The Test Equipment

We have a lot of test equipment – everything that makes it possible to ensure the item on the bench is in 100% working order. All our equipment is regularly PAT tested, calibrated and ESD safety checked to make sure we conform to current standards. Our equipment includes:

- Siglent, Gould and Rigol Oscilloscopes

- Siglent and Feedback Signal Generators

- Fluke and GW Instek Multimeters & Current Clamp

- Siglent & Manson Bench DC Power supply

- Pace, Weller, RSPRO and Aoyue Soldering Iron, Fume Extractor, Hot Air and Desoldering Stations

- Custom built Load Boxes with Stereo 2/4/8/16Ω 800W & 1600W loads

- PAT Tester

- AVO VCM MKIII Valve Characteristic Meter & Tester

- Variac and Galvanic Isolation Transformer

Other Machinery

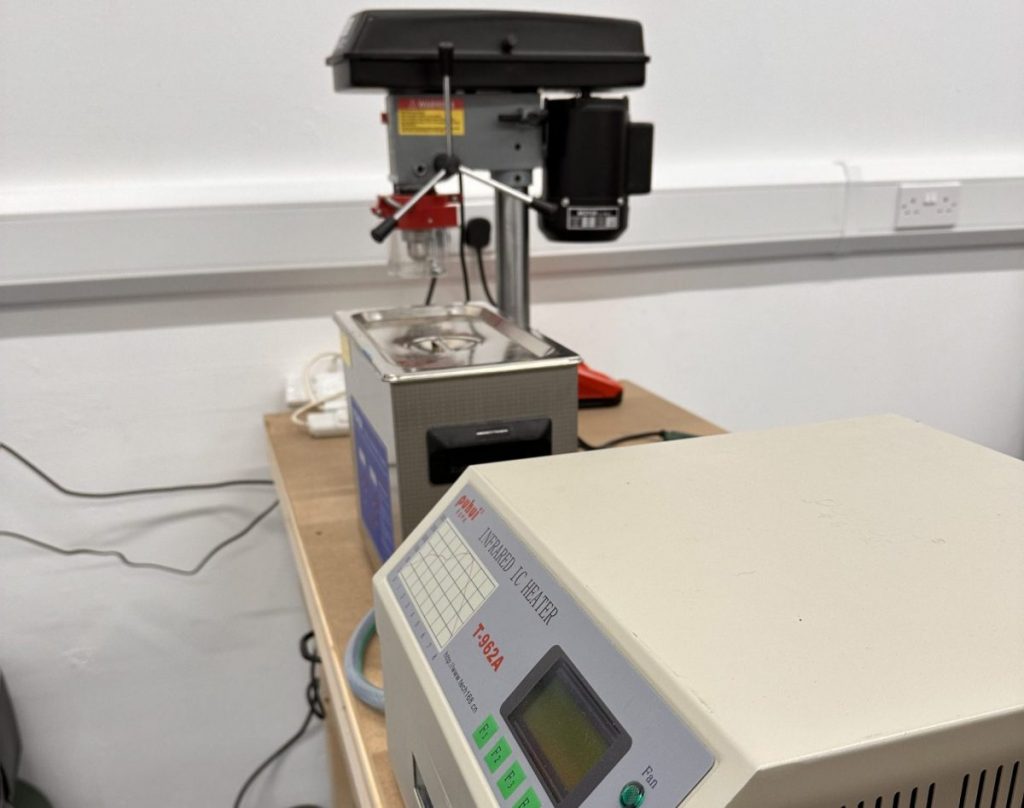

We also have various other machines that we use regularly including a pilar drill, an ultra sonic cleaner, custom modified reflow oven as well as access to various CNC machines and a spray booth.

We can also fabricate custom sheet metal using our partners across the UK.